We want to be more than the sum of our parts.

A need to exceed customer expectations is written into Mesekon’s DNA. We don’t just fabricate steel structures.

We listen to customer needs and wishes when it comes to both structures and the production process. In collaboration with our customers, we develop optimized solutions that boost production efficiency and extend the lifecycle of the equipment.

Our goal is growth and development – for all of us.

Over EUR 10 million in net sales

Mesekon doesn’t believe in quick profits. We believe in steady growth. Steady growth guarantees delivery reliability and work for people now and in the future.

More than 50 professionals

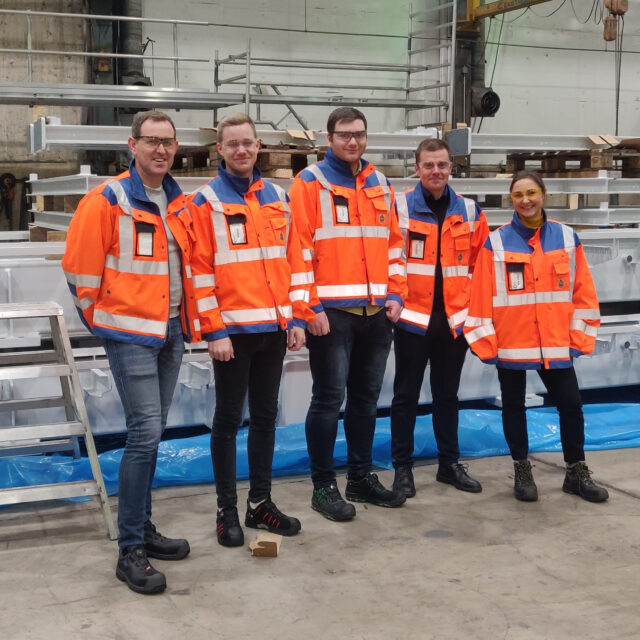

Successful work is achieved by a seamlessly operating team. We ensure a high level of competence through training. A standardized process helps us work as one. Our occupational safety culture is steered by the ISO 45001 standard.

From steel to finished product under one roof

Mesekon shapes steel into customized structures. Assembly and machining turn steel structures into equipment, using in-house expertise and our own production facilities and equipment.

Mesekon’s operations are defined by quality.

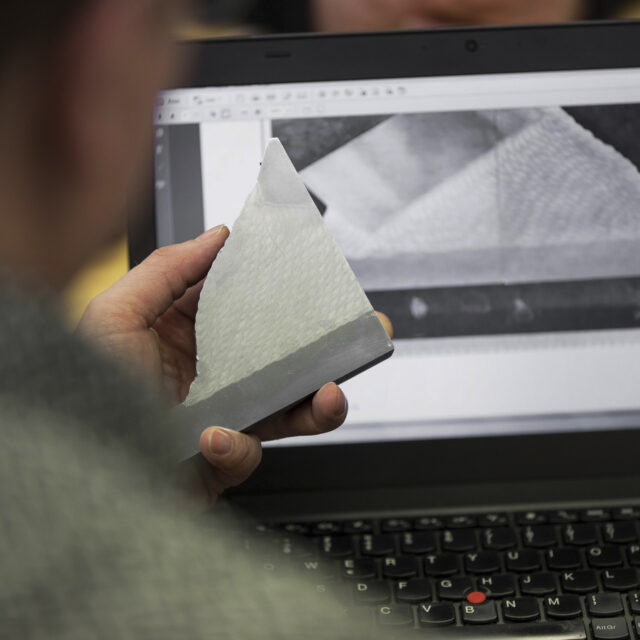

Mesekon’s quality is ensured through successful processes and a high level of expertise. Since 2015, our operations have been steered by an EN ISO 9001‑compliant quality management system. Our production uses welding procedures that comply with the EN, ASME and NORSOK standards. The high standard of welding is guaranteed by our EN ISO 3834-2 certification and by our welders’ qualifications compliant with various international standards.

Our certifications:

- ISO 9001

- ISO 45001

- ISO 3834-2

Customers at the core

A need to exceed customer expectations is written into Mesekon’s DNA. We don’t just fabricate steel structures. At Mesekon, we shape steel structures to meet customers’ wishes.

We listen to customer needs and wishes when it comes to both structures and the manufacturing process. In collaboration with our customers, we develop optimized solutions that increase production efficiency and extend the lifecycle of the equipment.

Mesekon’s quality management and documentation process meets customers’ quality management and reporting obligations by enabling comprehensive traceability.

We focus on personnel’s well-being

Only healthy and happy employees and an efficient work environment enable effective and high-quality work. Since 2018, we have improved our safety culture using the ISO 45001 standard’s model. Long-term safety and health development creates comprehensive well-being for employees and results in, for instance, fewer accidents and absences due to illness.

We work in a safe and healthy environment.

Nobody is born a professional – at Mesekon we challenge our own and customers’ expertise

Mesekon is in the habit of challenging itself and its partners in developing working methods and fabricability. Our goal is to serve the entire supply and value chain more extensively than before. We believe in persistence and openness, which has led to long-standing employment and customer relationships where both sides support each other’s growth.

We support going above and beyond at work and in sports

Miina Vaittinen’s summer job is deepening her ability to read blueprints and her insight into quality management and documentation at a mechanical engineering company