A steel structure heavyweight that loves to challenge and be challenged

We manufacture process equipment for various industries – with three decades of experience and certified expertise.

Verified and documented manufacturing process yields 100% traceable process equipment.

Welding and plate & pipe work

Competent production control and solid expertise guarantee high quality

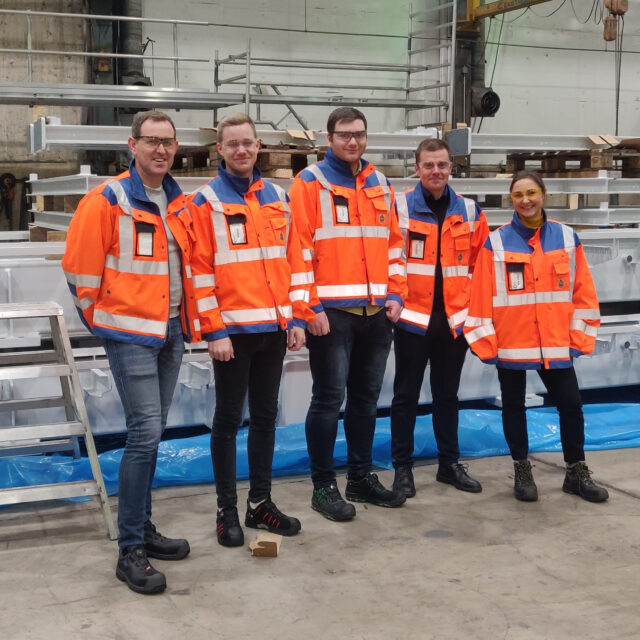

The manufacture of heavy and medium-heavy welded steel structures forms the core of Mesekon’s operations. In collaboration with our customers, we optimize the structure and fabricability of our products.

We develop our processes and production methods continuously. At Mesekon, quality stems from competent production control and a professional touch. The process is steered by IWS-qualified supervisors and IWE-qualified welding coordination. Our skilled welders are responsible for the quality of the work – at Mesekon, each welder has an SFS-EN 9606-1 qualification and our welding processes comply with the EN, ASME and NORSOK standards.

Vema Lift Oy:

“Our product is challenging in terms of fabrication, so Mesekon’s competent and expert personnel play a key role in our success. In using new high-strength steel grades, the manufacturer’s modern technical welding expertise helps to uncover the full benefits offered by the material.”

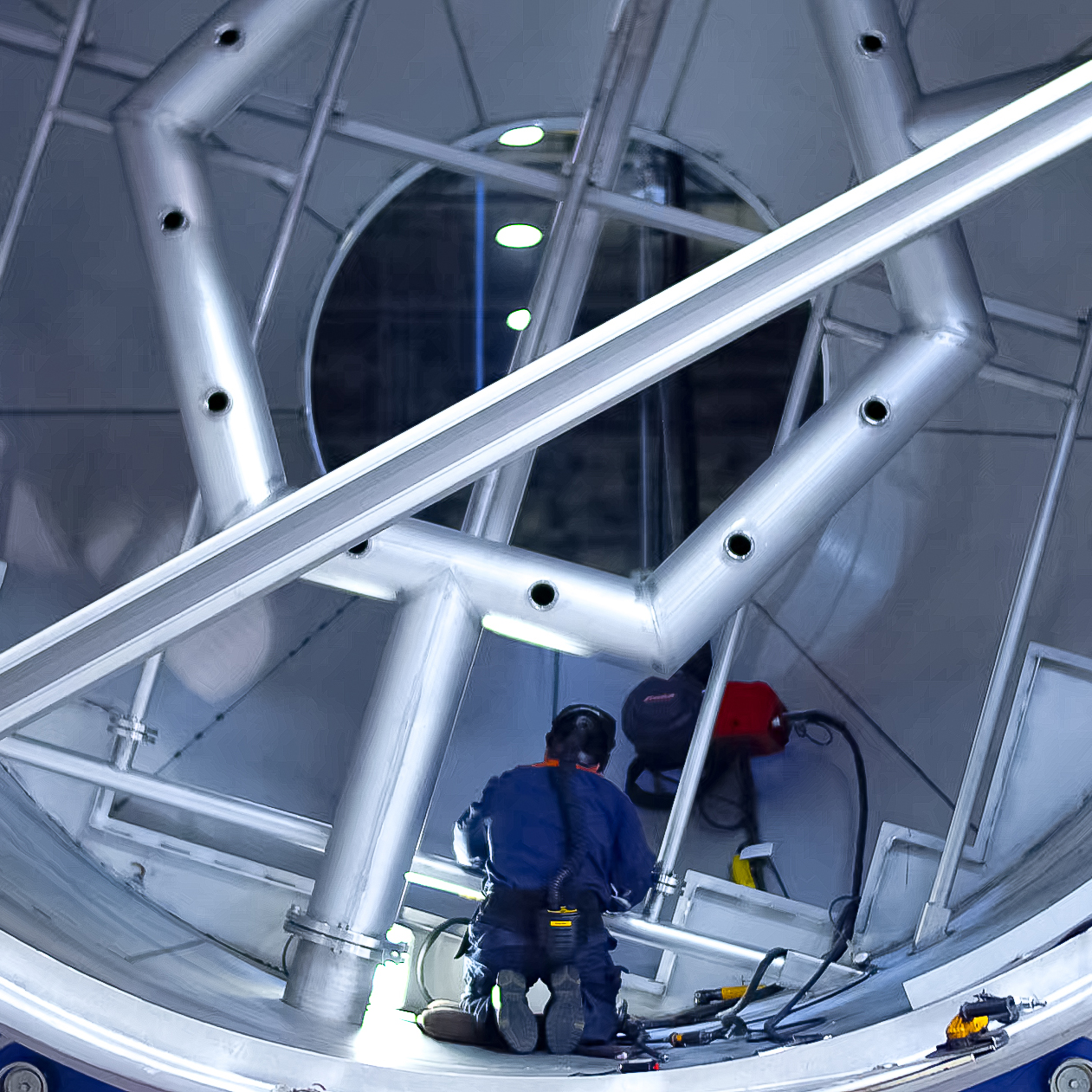

Assembly

Comprehensive partner

We take charge of extensive assembly projects as a strategic partner for globally respected technology industry companies.

Even your most challenging projects are in safe hands with our experienced and independent personnel. We can scale the team’s size up or down depending on the need, but the end result is always top notch, no matter the project’s size.

Our assembly team is responsible for both mechanical and hydraulic assembly, and electric installation work is also available through our partner network.

Framo:

“For Framo, maintaining the best possible quality of products and documentation is essential, and we expect the same from our suppliers. Mesekon’s working methods focus on problem solving and are flexible throughout the manufacture of our offshore products. We have relied on Mesekon and developed our collaboration for decades.”

Machining

CNC machining under the same roof

We also machine most of the steel structures that we weld. The machining takes place at our plant and using our own machine tools: we have CNC boring machines for both heavy and medium-heavy applications.

When necessary, our established partner network complements our in-house machinery with additional resources.

Langh Tech Oy:

“Together with Mesekon, we have built a supply chain where customers enjoy efficient, expert and fast project management.”

Co-creation extends the lifecycle of products and increases productivity. Our standardized manufacturing process ensures high quality and we create the required documentation.

From raw material to machined product under one roof

Mesekon’s production facilities are where customer needs and skilled personnel and technology meet. As process development, fabrication, assembly and machining all take place under one roof, delivery reliability and cost effectiveness are guaranteed.

Only verified and documented quality is good enough

Mesekon’s quality management and documentation process meets customers’ quality management and reporting obligations by enabling comprehensive traceability.

Comprehensive welding expertise

Our customers are leading companies in their fields and always coming up with new innovations. This also drives Mesekon to continuously evolve its competence and operations. We invest in our personnel’s expertise: our supervisors have the IWS qualification, welding coordination is IWE-qualified and all of our welders have the SFS-EN 9606-1 qualification. We can handle 22 materials qualified for welding and have 151 procedure test approvals at our workshop.

Openness and expertise make for a straightforward sulphur scrubber supply chain

Langh Tech Oy

"lt is important in a sulphur scrubber supply chain to serve the end customer flexibility. Together with Mesekon, we have built a supply chain where customers receive efficient, qualified and fast project services. Local cooperation and open interaction have played a key role in improving our products, both when it comes to the manufacturing technique and the process itself."

"Our product is challenging in terms of fabrication, so Mesekon's competent and expert personnel play a key role in our success."

Vema Lift Oy

"For Framo, maintaining the best possible quality of products and documentation is essential, and we expect the same from our suppliers."

Framo AS