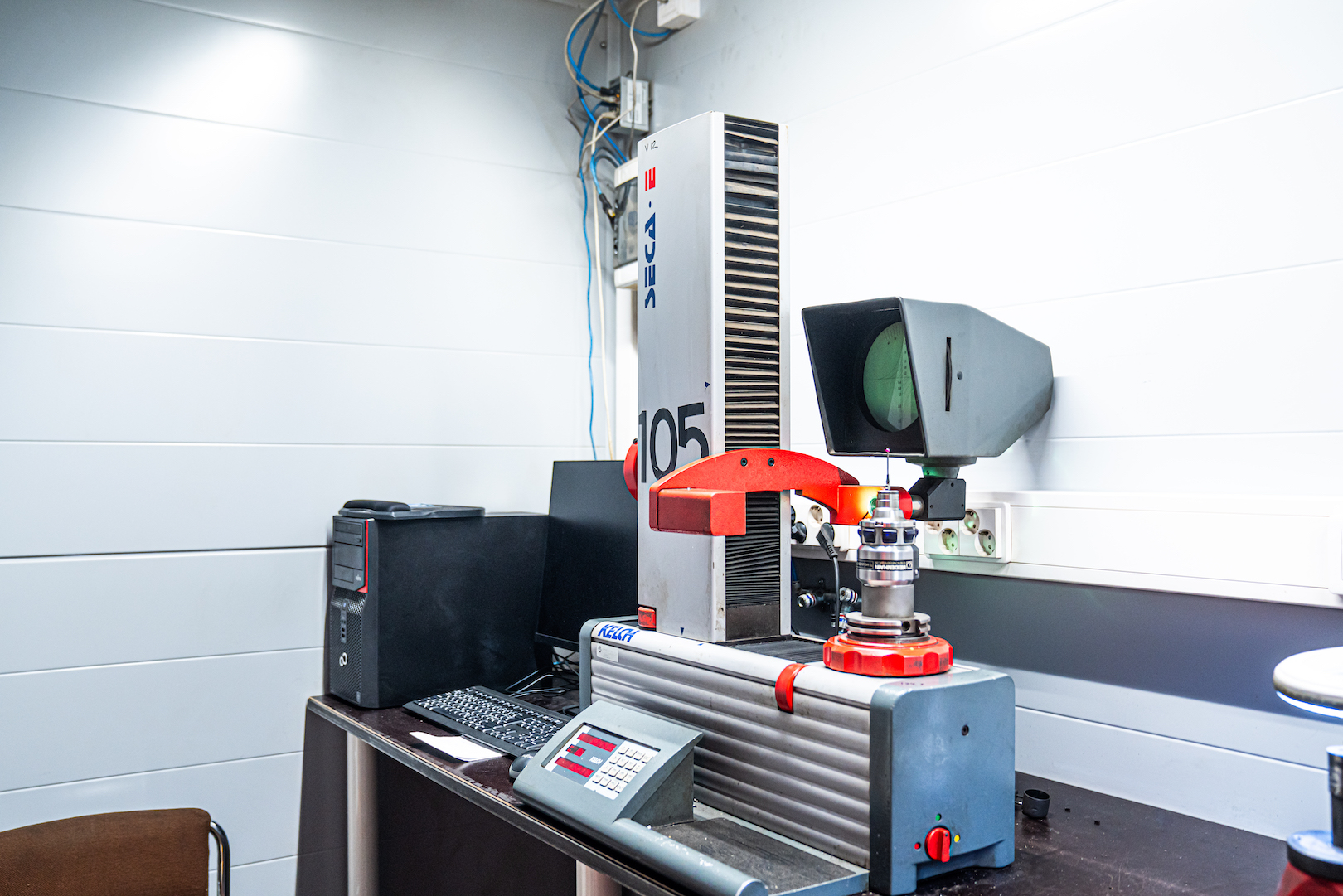

One of the key strengths of Mesekon’s boring capabilities is the wide selection of tools, which enables accurate and flexible machining across different metals. Our CNC-controlled boring machines are equipped with a 3D touch probe, allowing for precise part positioning and measurement.

– The touch probe system detects the exact location of the part and ensures optimal setup accuracy. This minimizes potential measurement errors and ensures sufficient machining allowance, says Timo Mäki, Production Manager at Mesekon.

Thanks to our two-machine setup, we can guarantee uninterrupted production and consistent quality – even during maintenance periods.

– If one machine requires servicing, production continues on the other without delays. Our multi-shift operation and experienced staff ensure high capacity and reliable lead times, Mäki adds.

Partnership-driven process development

At Mesekon, we believe in taking a holistic approach to manufacturing and design. Through close cooperation with our customers, we identify opportunities to improve product functionality, manufacturability, and cost-efficiency.

– We often detect small design flaws early in the process and suggest improvements that enhance the final product. We provide valuable design feedback and develop better production methods together with our customers, Mäki explains.

Even minor adjustments can significantly streamline the manufacturing process. For instance, removing unnecessary material already during the design phase can reduce raw material and production costs.

– We also consider accessibility during machining and assembly. Sometimes, small design tweaks can make production smoother. Our customers appreciate this proactive and solution-focused approach, says Mäki.

Being part of the Stairon Group gives us a unique edge: we can take machining requirements into account already during sheet metal processing, reducing the need for later operations and speeding up production.

– This integrated approach results in faster lead times and more efficient workflows, notes Tero Nättiaho, Sales Director at Mesekon.

Our aim is to build long-lasting relationships with our customers, based on openness, collaboration, and continuous improvement.

– To maintain a competitive edge in domestic industry, we need to work together to find sustainable and innovative solutions, Nättiaho concludes.

Mesekon’s boring capabilities:

CNC-Boring and milling machine TOS WHN 13

- spindle 130 mm, ISO 50

- X=5000, Y=3000, Z=2000, W=800 mm

- table 2500 x 1800 mm, max load 20 t.

- control system Heidenhain TNC 530

CNC-Boring and milling machine TOS WHN 13.8

- spindle 130 mm, ISO 50

- X=4000, Y=2500, Z=1250, W=800 mm

- table 2200 x 1800 mm, max load 12 t.

- control system Heidenhain TNC 426